usp class vi vs iso 10993

A more rigorous standard for the biological. Take an ASTM D2000 call out.

Bal Seal Engineering Achieves Usp Class Vi And Iso 10993 5 Compliance For Medical Sealing Polymers Bal Seal Engineering

Steve Melito August 5 2020.

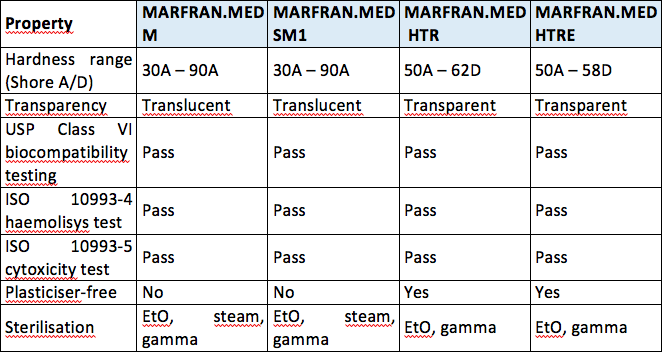

. Medical Molding and Biocompatible Rubber. ISO 10993 is designed for medical products that remain permanently or for a very long time in the human body so for. Typically the terms USP Class VI or ISO 10993 materials are used.

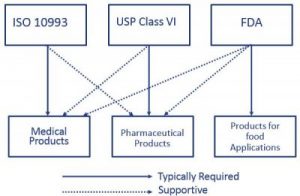

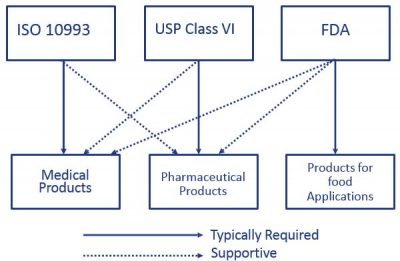

USP class VI versus ISO 10993. These international standards refer to the testing requirements for bio-compatibility most commonly used in the medical sector and meet very high standards of. Unlike other rubber standards theres no one standard that engineers use for an approval.

However Class VI also requires subacute toxicity and implantation. For this reason the FDA provides a standard 21 CFR1772600 defining allowable rubber compound ingredients and extractibles based on toxicity and carcinogenicity. If yes to the first question then USP Class VI is not a relevant qualification for it.

USP Class VI ISO 10993-5 Cytotoxicity In-Vitro ISO 10993-3 Ames Genotoxicity ISO 10993-11 Systemic Toxicity In-Vivo ISO 10993-4 Hemolysis Indirect European Pharmacopeia 329. USP Class VI Testing is only one standard of biocompatibility however. The most stringent Class VI requires three types of tests.

Iso 10993 vs. Though not a limited series of tests some biocompatibility requirements for medical devices may exceed the testing performed in USP Class VI. USP Class VI demands an intracutaneous irritation test.

Rob Pruyn August 5 2020 Custom. A more rigorous standard for the biological. Though not a limited series of tests some biocompatibility requirements for medical devices may exceed the testing performed in USP Class VI.

ISO 134852016 - Medical Device Quality Management Systems. Biocompatibility - USP Class VI vs. Though not a limited series of tests some biocompatibility requirements for medical devices may exceed.

USP Class VI and ISO 10993. USP Class VI vs. Inside Rubber Magazine Profiles The Rubber.

You might establish biocompatibility via making the device of a Recognized Consensus. Food Grade or USP Class IV Materials for. The materials listed below are ideal for.

USP class qualification was a key method for establishing material biocompatibility at least as far back as 1976 until the. A selection of Figure 4 VisiJet Accura and DuraForm plastic materials have met the requirements of ISO 10993-5 -10 or USP Class VI testing. USP Class VI and ISO 10993.

Iso 10993 is designed for medical products that remain permanently or for a very long time in the human body so for shorter applications a usp class vi or even a lower usp class certification is. So does ISO 10993. May 1 2009.

Below youll find a list of all posts that have been tagged as USP Class VI ISO 10993 vs. These international standards refer to the testing requirements for bio-compatibility most commonly used in the medical sector and meet very high standards of.

Medical Grade Cyanoacrylate Super Glue Iso 10993 And Usp Class Vi

Understanding Food Grade Vs Biocompatibility For Medical Device Materials Medical Product Outsourcing

Brilliant Mind The World Of Tubing For Medical Use Medical Plastics News

Regulatory Guidelines For Biocompatibility Safety Testing Mddionline Com

Usp31nf26s1 C1031 General Chapters 1031 The Biocompatibility Of Materials Used In Drug Containers Medical Devices And Implants

Usp Class Vi Foster Corporation

Iso 10993 Vs Usp Class Vi Medical Molding And Bicompatible Rubber The Rubber Group

Usp Class Vi Certification Presco Marking Products And Engineered Films

Understanding Food Grade Vs Biocompatibility For Medical Device Materials Medical Product Outsourcing

Material Selection Medical Injection Molding Xcentric Mold

Regulatory Guidelines For Biocompatibility Safety Testing Mddionline Com

Usp31nf26s1 C1031 General Chapters 1031 The Biocompatibility Of Materials Used In Drug Containers Medical Devices And Implants

Usp Class Vi Foster Corporation

Usp31nf26s1 C1031 General Chapters 1031 The Biocompatibility Of Materials Used In Drug Containers Medical Devices And Implants